Imbalance of rotating components is one of the most common sources of machine faults in rotating assemblies, pumps and fans and is a major cause of complete equipment failure. Most people’s awareness of balancing is limited to knowing a car’s wheels and tyres that must be balanced, to avoid steering-wheel shudder and uneven tyre wear.

Equipment failures can have dramatic impact on a plant’s production and manufacturing commitments. If there is a grumble or a groan, a banging or shaking, or if things just don’t seem right it may be time to get it checked out. This can be critical especially as up to half of electric motor breakdowns are caused by damaged bearings, due mostly to the vibration occurred by the rotor’s imbalance.

Industrial balancing and vibration analysis on rotating machinery enables the early detection of faults before breakdown, and assists commercial and industrial facilities reduce their maintenance costs and unscheduled downtime. Dynamic Balancing of this rotating equipment offers many benefits, including:

- Increasing equipment’s performance and longevity, ensures optimum performance of machinery

- Improves running conditions to reduce ongoing maintenance costs and maximise return on investment, improving equipment operating costs and economy

- Lengthens service life. Bearings, suspensions, housings and foundations can be subjected to very high stresses caused by vibration resulting from unbalance and these result in greater wear.

- Products with unbalanced parts often have a shorter service life.

- Decreasing breakdowns and unscheduled downtime. Vibrations can reduce the frictional grip of screwed and clamped connections. Electric switches can be destroyed by vibration, pipes and cables can fracture at the connections.

- Reduces chances of equipment failure, vibration and imbalance can lead to catastrophic failure.

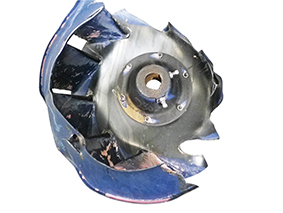

Industrial balancing is the procedure where the mass distribution of a product, be it a pump, roller, impeller or the like, is accurately measured and suitably adjusted. This will ensure that the forces on the bearings, at a frequency corresponding to the devices operational speed, are within limits as specified in International Standards, such as ISO 1940-1:2003 Mechanical vibration (Balance quality requirements for rotors in a constant rigid state).

Precision Balancing has been offering in house and on site dynamic balancing and vibration analysis services since 1989 and have the equipment, skills and experience to satisfy your industrial balancing requirements. Owned and operated by qualified mechanical engineers, members of the Australian Institution of Engineers, with years of experience in mechanical engineering and industrial balancing. Precision Balancing has been offering a range of specialised balancing services for pump impellers since the company began, and has worked on a huge range of models and sizes. Precision Balancing offer personalised service including on site balancing, and quick turnaround or emergency after hours breakdown services.

For more information on how industrial balancing can help you in achieving machine harmony contact us.